Inventor CAM Templates

One of the lesser-known features of Fusion Manufacture and Inventor CAM is creating templates. This process can substantially improve workflow, reducing non-essential steps and therefore reducing programming time considerably.

Scroll for the step by step guide.

Your Project

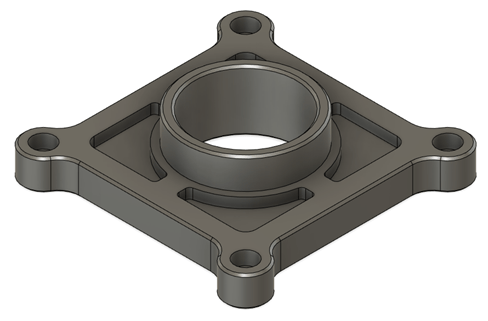

Here’s the scenario: You’ve painstakingly produced a CAM program for the component shown below, using features such as 3D Adaptive, 2D Contour and Drilling cycles etc.

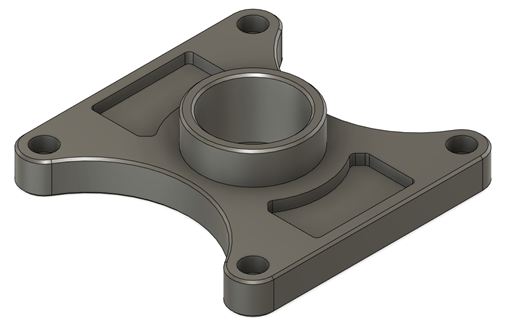

Now imagine your frustration approaching a new task when you see that the component (shown below) is very similar to the one previously worked on. Sure, the overall shape and sizes are different but the whole machining strategy is practically identical, as are the tools needed.

A quick way to rectify this is to create a template. It’s this simple:

- Select all the features of the initial program, right-click and select Store as Template

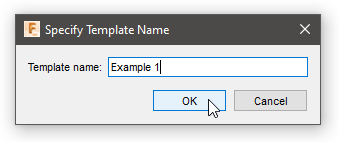

- Name the template (Named Example 1 for this demonstration).

- Navigate to the new component environment and create a new Setup.

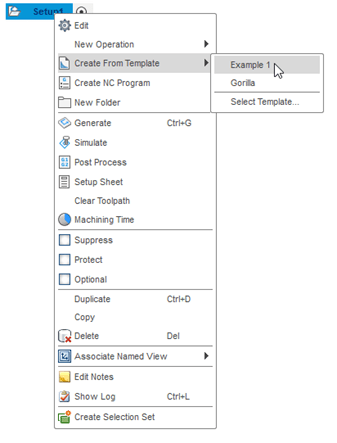

- Right-click the new Setup and select Create from Template > Example 1

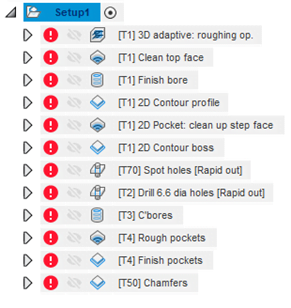

- All the features from the previous program have now been allocated to the new program. As you can see, each feature has an error, this is because the new geometry or height reference selection is required.

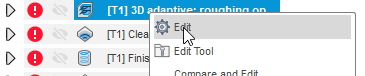

- Now right-click on a feature and select Edit to adapt accordingly. Select the new geometry, change the heights/depths of cut etc. if required but, as you will now see, all the foundation work has already been completed based on the original program.

- If any features aren’t required they can be suppressed or deleted.

- Rename the features to suit the new component.

- Lastly, sit back and congratulate yourself for saving a huge amount of time!

For more information about Inventor CAM and Fusion, contact us

For more information please contact us today!