Need to export a large design assembly, but don’t want to give out all of the detailed information? Want to export the assembly while reducing the file size? Hoping to improve performance in downstream processes by reducing assembly model complexity? Export using Shrinkwrap can help.

Large assemblies can be tricky to work with. Some Inventor assemblies can be as large as 100,000 occurrences and 10,000 unique parts or more. An occurrence is a reference to a part or subassembly from the main assembly. A more typical large assembly probably contains 3,000 – 5,000.

With so many parts and sub-assemblies, it can be tricky to share your assembly with others and provide them with the right amount of information required.

Need to share a design with someone, but don’t want to give out all of the detailed information? The shrinkwrap command can help you model size, load time and details.

Why Shrinkwrap your Inventor Files?

What benefits do simplified parts provide?

- Simple to use

- Significant reduction in file size for large assemblies and complex parts.

- Reduced time to open an assembly using a simplified assembly substitute Model State.

- Improved performance when viewing or working with large assemblies and complex parts.

- Protect intellectual property by removing features and internal components.

- Improved performance as BIM content

So how do you Reduce your Inventor File Size using Shrinkwrap

000 occurrences with 1,000 to 2,000 parts.

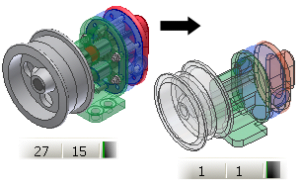

Shrinkwrap works by reducing the number of faces in a part or parts within a subassembly. Use Shrinkwrap to create a simplified single part representation of an assembly to improve capacity and performance in downstream assemblies or applications. Shrinkwrap uses the derived component command in the background to create a single part from an assembly.

How to Export with Shrinkwrap

Creating a shrink-wrapped component is simple. The component is created from inside the assembly file, eliminating the need to derive the assembly into a new part. Not only is it all done automatically, but the substitute will normally be much smaller than the original derived part approach.

- Select the Shrinkwrap command from inside the top assembly. The following dialog will appear, allowing you to create the shrinkwrap part.

- Because you are creating a shrinkwrap from the top level assembly, the command will assume, by default, that you want to shrinkwrap all of the parts and subassemblies that exist at the top level.

- As you progress through creating the shrinkwrap – you will be presented with the Derived Assembly dialog box where you can choose which parts and subassemblies will be added into the shrinkwrap.

- Once you have accepted the settings in the Derived Assembly dialog and picked OK, not only will the shrinkwrap be created as an individual IPT, but a new Substitute Level of Detail will be added at the top assembly level.

- Be absolutely sure to pick Save at this point to ensure that the Substitute Level of Detail is saved in the assembly.

- After saving, you will find you can quickly toggle between the original assembly Master Level of Detail and the shrink-wrapped Substitute Level of Detail. During the save, the new shrinkwrap part file will also be saved.

Boost Efficiency with Advanced Assembly Modeling in Quadra’s Inventor Training

Considering the importance of mastering advanced assembly modelling techniques in Autodesk Inventor, it’s worth exploring how enrolling in the corresponding training course can further enhance your ability to optimise large assemblies, reduce file sizes, and improve overall performance.

By enrolling in Quadra’s Inventor Advanced Assembly Modelling training, individuals can deepen their understanding of assembly modelling techniques, including top-down design workflows and model simplification tools. They will learn how to effectively manage complex assemblies, reduce file sizes, and enhance performance through advanced features like positional representations and iAssemblies.

Additionally, mastering rendering and animation with Autodesk Inventor Studio can further streamline the process of visualising and communicating design concepts, aligning with the goal of optimising assembly efficiency and collaboration.

For more information please contact us today!